Smart manufacturing for sustainable development

In the context of the strong development of Industry 4.0, many enterprises in Binh Duong clearly identify that smart production and automation are not only inevitable trends but also a lever to improve competitiveness and sustainable development.

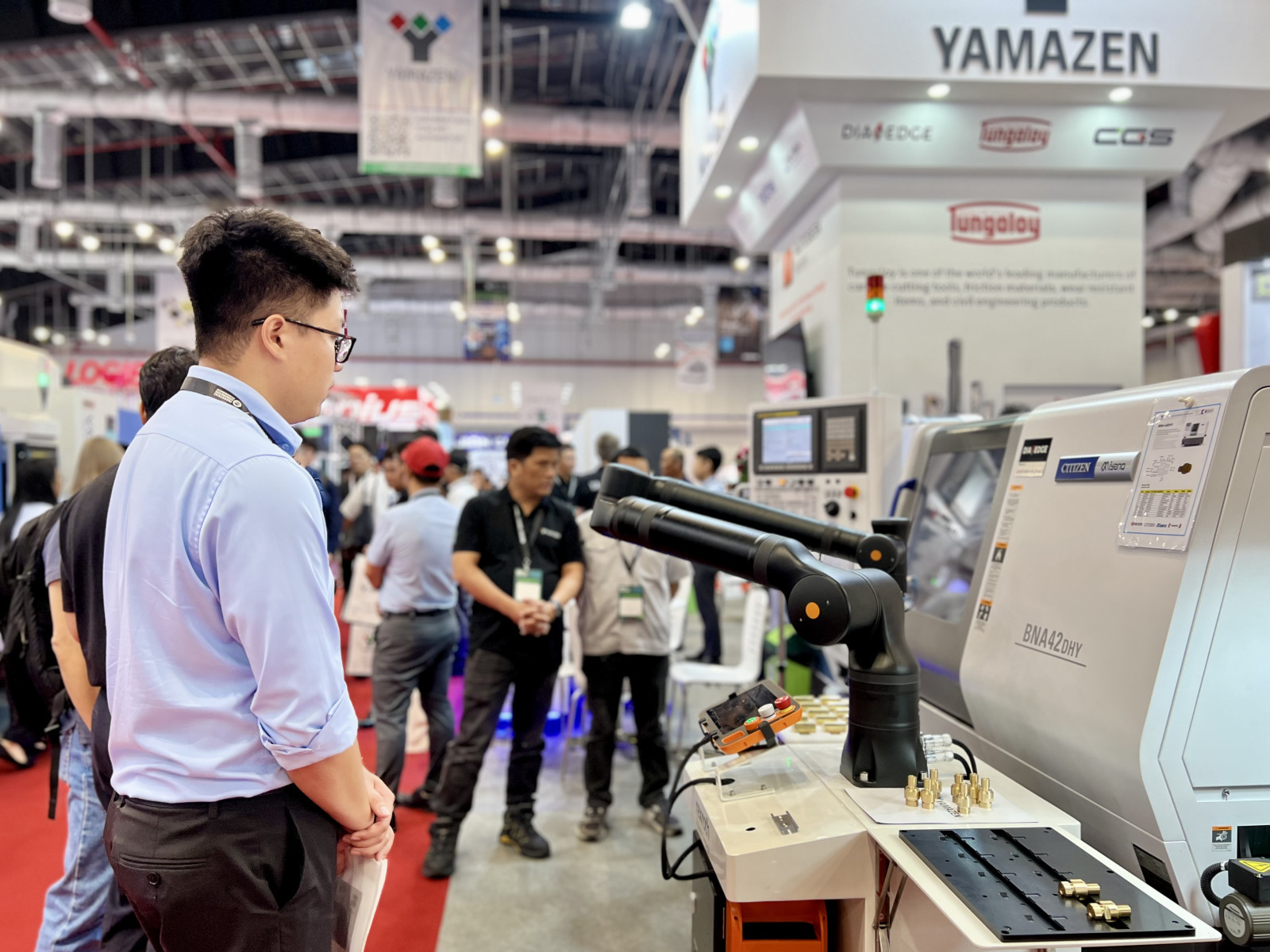

To meet the increasing demands of customers, many businesses in the province have applyed modern technology and machinery. In photo: Customers learn about modern equipment and machinery at the VIMF 2024 Exhibition Fair held in Binh Duong recently.

Catch up with the trend

Although it has only been in operation for a few years, IGB Automotive Vietnam Co., Ltd. (Song Than 3 Industrial Park), specializing in manufacturing and supplying sensors and electric heating components for car seats, continuously has export orders to European countries. Mr. Tran Quy Cuong, Factory Director of IGB Automotive Vietnam Co., Ltd., said that the company's customers are famous car manufacturers in the world, so the product requirements are very strict. To meet the increasing demands of customers, the company has invested in automated production lines. The application of modern technology and machinery into production requires workers to have high technical skills and expertise to master modern technology.

Mr. Tran Do Hoai Bao, Director of He Vi Production and Trade Joint Stock Company (Ben Cat City), shared that the company produces paper packaging, a field with strong competition in the market, forcing the company to constantly innovate. Enterprises are promoting the application of science and technology in production and business, such as digital information technology and digital manufacturing technology. From input to output of the products, the company monitor the process using modern technology machinery to ensure quality and enhance product competitiveness. These technologies allow businesses to make their products independently without depending on a third party.

It can be seen that digital transformation is helping domestic enterprises and foreign-invested (FDI) enterprises reduce the pressure of labor shortage when opening more factories and production lines. Meanwhile, most products apply modern technology with diverse designs and quality, meeting the increasing needs of domestic and foreign customers. Particularly for small and medium enterprises, digital transformation is also creating breakthroughs in production and business. Many enterprises have risen to affirm their brands, signed large contracts, and gradually participated in the global product supply chain.

Apply technology, create breakthroughs

Mr. Nguyen Trong Luat, General Director of Cicor Vietnam, said: “As one of the fastest growing electronics manufacturers in Europe, specializing in high technology, Circo has been present in Binh Duong for 24 years. We have built our fourth factory in Binh Duong, with an area of 12,000m2. Our investment in the fourth factory not only doubles the group's production capacity in Vietnam, but also further develops Cicor's technical capabilities. Recently, we have transferred technology from Switzerland to Vietnam. Customers are increasingly demanding on products, thus we must also focus on improving and applying modern technology to facilitate production in Vietnam. Up to now, Cicor Vietnam factory has reached the same level as manufacturing factories in Switzerland, Germany and the United States.

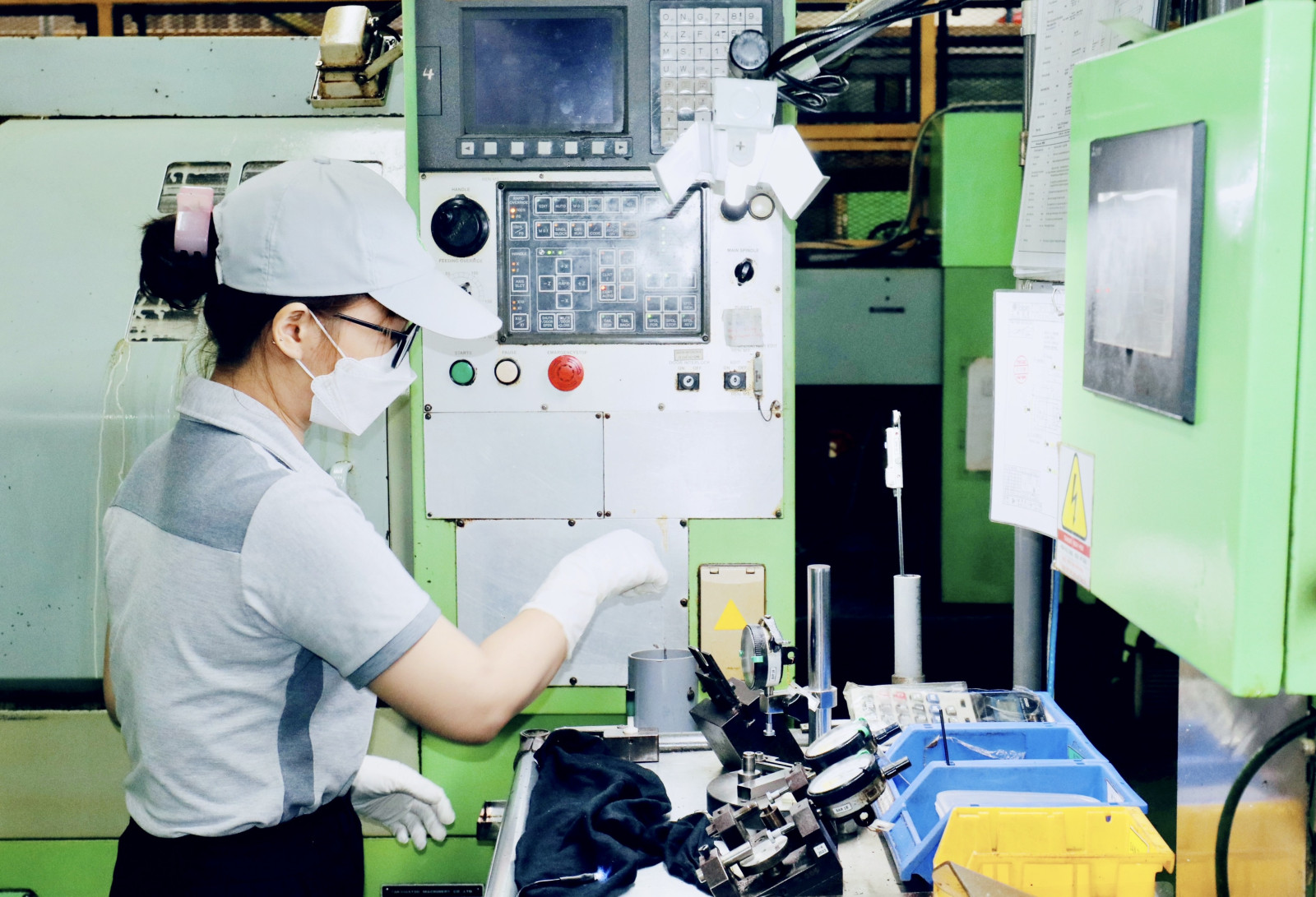

Production activities at Takako Vietnam Co., Ltd.

According to Mr. Le Duy Nhat Luan, Technical Director of Takako Vietnam Co., Ltd. (Vietnam - Singapore Industrial Park 1), if previously the company had to arrange 4 workers to operate the production line, from 2016 to now, thanks to the application of modern technology, the company only needs 1 engineer to operate but still increases productivity, product quality, and at the same time helps the company improve production costs.

In the current development process, Binh Duong always takes enterprises as the center for innovation activities, focusing on key industries and fields following the trend of the 4.0 industrial revolution. Binh Duong aims to become a smart manufacturing industrial center, widely applying advanced automation solutions into production, contributing to improving productivity, quality, efficiency and competitiveness of the province's industry. To realize the goal, Binh Duong is preparing a strategy and synchronous solutions for transport infrastructure, technology, developing high-quality human resources, supporting enterprises in researching and applying new technologies to improve production and management efficiency.

|

According to Mr. Nguyen Truong Thi, Deputy Director of the Provincial Department of Industry and Trade, to improve operational efficiency, restore production and business, as well as seize opportunities from the 4.0 industrial revolution, many enterprises in Binh Duong are promoting digital transformation, applying science and technology into production and business. Binh Duong always creates favorable conditions for local enterprises to invest in technology, production lines, improve competitiveness and build reputation on the market. |

Reported by Ngoc Thanh - Translated by Ngoc Huynh